Our Products

Why use Cement Additives?

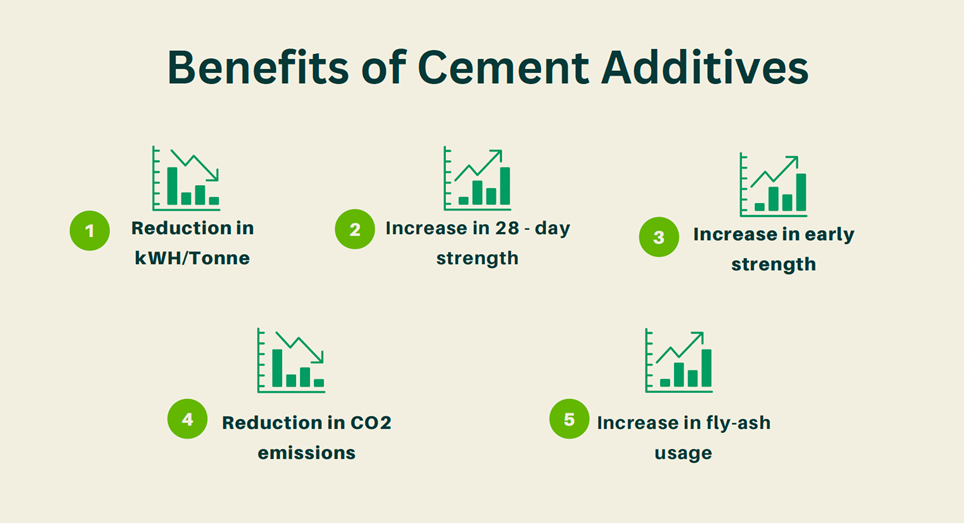

Cement manufacturing compounds improve the performance and efficiency of the cement grinding process. This, further, improves the performance and quality of the finished cement and is aimed at reducing overall manufacturing costs.

Quality Improvers and Grinding Aid

Grinding Aid

- Reduction in kWh/T for Cement grinding

- Increased Production rate

- Reduction in Mill run hours

- Improved Cement handling characteristics

- Improved grinding efficiency leading to narrower particle size distribution of the final product

- Increased separation efficiency from improved grinding efficiency

- Lesser coarser particles, and less over grinding

- Improvement in strengths due to narrower particle size distribution

Quality Improver

- Grinding aid benefit similar to that of a Processing Additive

- Narrower Particle size distribution (Increase in RR Slope)

- Improved Cement performance characteristics and workability

- Improvement in cement strength

- Increase in early strength to the scale of 5% to 20% (1 Mpa to 5 Mpa @ 1 day, 2 Mpa to 10 Mpa @2 day strength)

- Increase in later strength to the scale of 5% to 15% (2 Mpa to 10 Mpa @ 28 day compressive strength).

- Or combination of both (all age strength enhancement in the range of 5% to 15%)

- Increase in setting time to the scale of 10 minutes to 40 minutes (Initial Set)

- Reduce setting time to the scale of 10 minutes to 40 minutes (Initial Set)

- Reduction in concrete water demand to the scale of 2% to 5%

- Reduced coating and reduced pack set